TE-BAR provides unequaled expertise in the design, manufacture and application of state-of-the-art purpose built machines developed to solve your industry needs. We have the experience to know and advise you as to when it is more cost effective to either refurbish your current machine or to purchase new.

If you are able to identify any the following then you may be a candidate for new equipment. If only one is problematic, a rebuild may be more cost effective for you.

- Does your machine meet your needs for size and production?

- Is your machine mechanically and electrically sound?

- Is your machine accurate, in good way alignment?

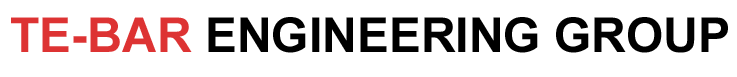

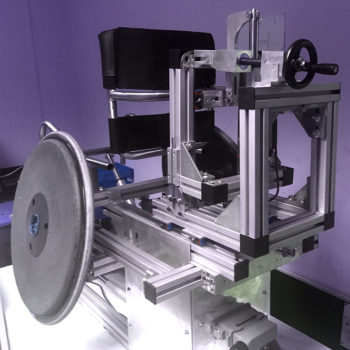

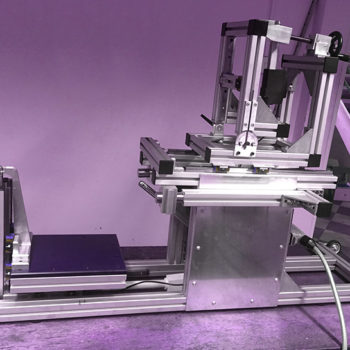

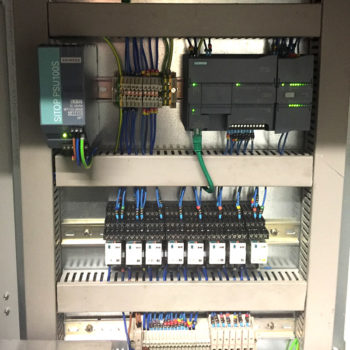

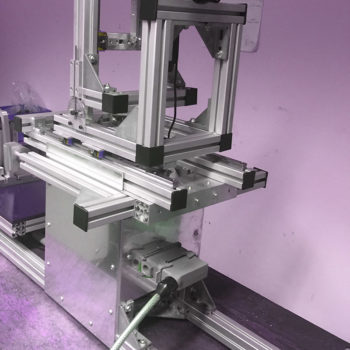

We have designed and built special purpose machinery, control systems, and special purpose tooling and automation that covers all types of industrial needs. By working closely with our clients our aim is to understand their needs and design bespoke machinery and tooling that is simple whilst still meeting all the necessary requirements.

This way we can manufacture a bespoke machine that is both reliable and cost effective