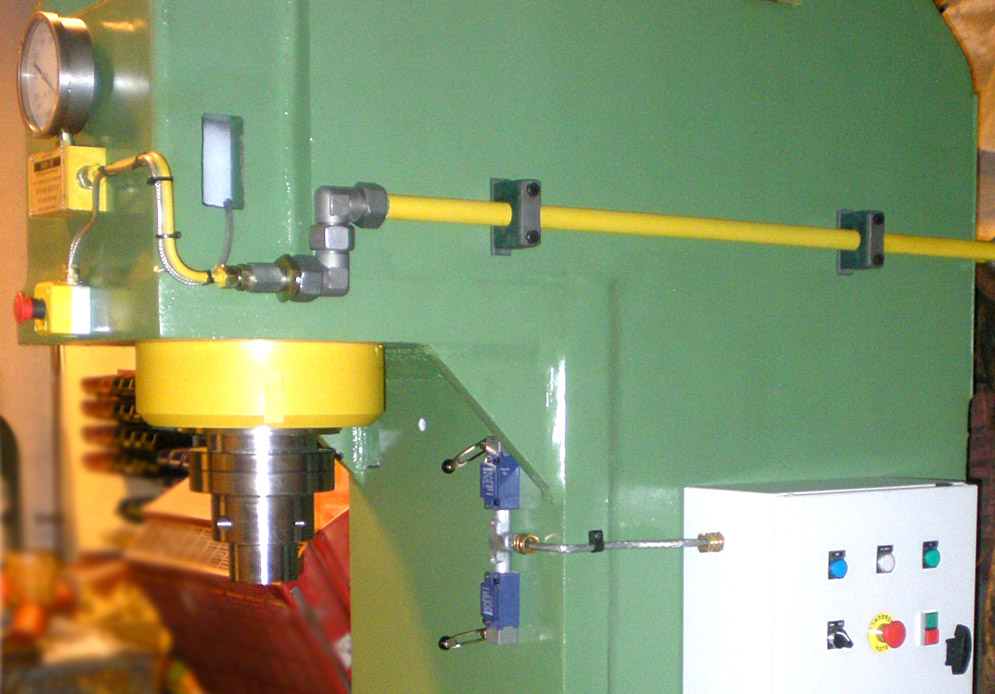

TE-BAR excels in machine tool reconditioning, rebuilding, and retrofitting and we are able to provide engineering analysis, CNC controls, way resurfacing, mechanical restoration, handscraping and flaking services.

TE-BAR has a team of dedicated time served engineers with experience in building machine tools of all types. If your machinery requires servicing or complete refurbishment we can reverse engineer a solution for you, regardless of original manufacture or age.

A machine tool re-conditioning programme includes an agreed specification, pre-work checks, alignment’s, accuracy and calibration verification (using conventional equipment, laser & ballbar).