LAB Engineering (South Wales) Ltd are specialists with 20 years experience in the machining of large components and assembly.

We provide fast turnaround and a cost effective accurate component manufacturing service second to none through the use of high tech machinery.

We are approved subcontractors for many large established companies including Timet, Tata, Lloyds British, Magor, and Calsonic Kansei and specialise in the machining of Titanium plate and bar.

LAB Eng are SNECMA Approved (French Aerospace) and the only UK company approved for machining SNECMA Titanium bars.

LAB ENG (South Wales) LTD

LAB Engineering Services include:

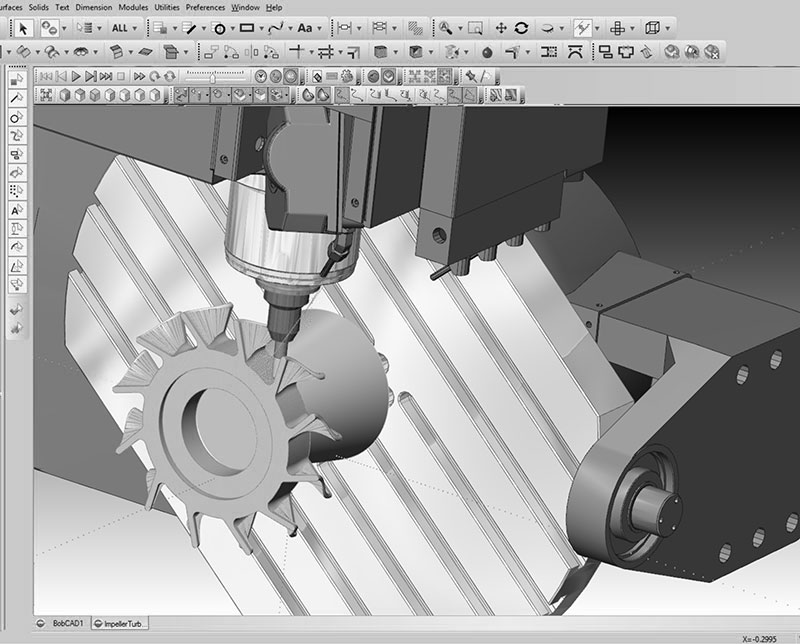

Large Scale CNC Turning

Large Scale CNC Milling

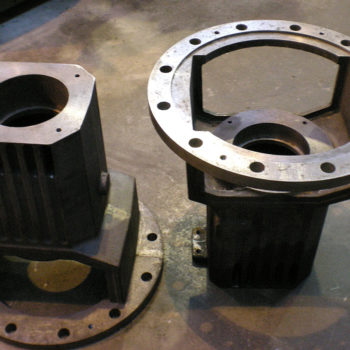

Maintenance and Refurbishment

General Engineering and Assembly

Large Capacity CNC Milling and Turning

LAB have large component capability for CNC Milling of 3m x 1m x 1m plus 5 CNC bedmills of various capacities.

We can also provide large component CNC Turning up to 550mm Dia x 1500 long with a 120mm through spindle, and also have a 255mm Dia x 800mm machine with bar feeder for bar feeding up to 90mm Dia.

Automated Turning produces more accurate cost effective parts faster.

We have 2 Hitatchi Seiki turning Cells which can produce 150mm x 150mm long components. These are equipped with loaders and parts turning units that enable the both ends of work to be turned without requiring operators. Hence customers projects can be completed quicker and more cost effectively.